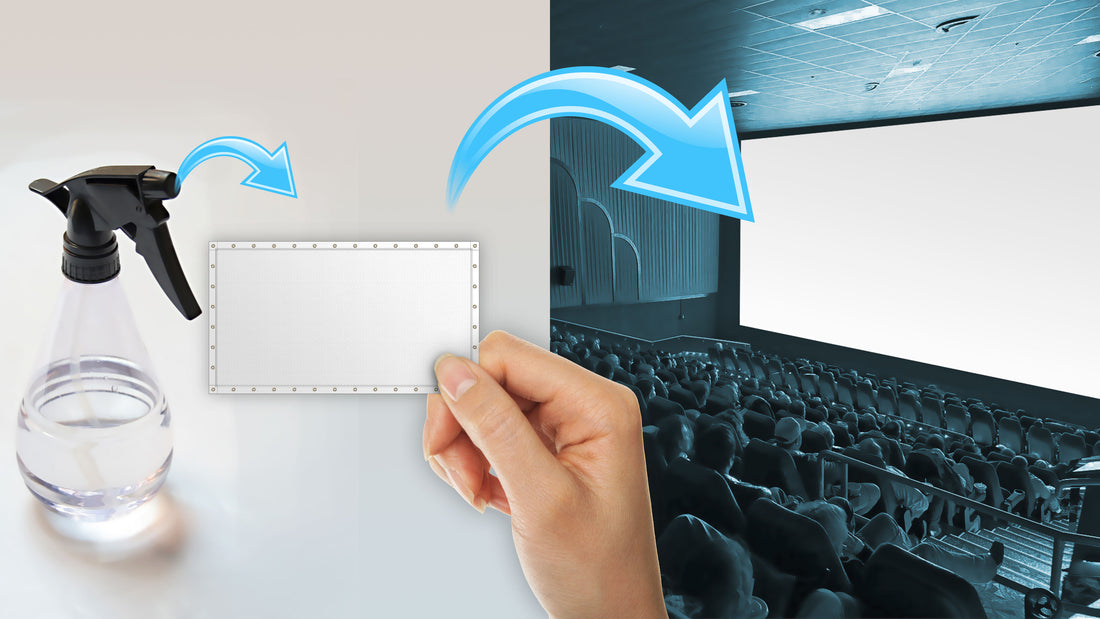

Expansive Cinema Screens Ship in Padded Envelopes, Then Expand to Full Size With the Addition of Water Prior to Installation.

Mesa, Ariz., April 1, 2015 – As a leader in the cinema, home theater, and Pro-AV screen industry, Severtson Corporation (www.severtsonscreens.com) has a history of creating top quality screens, screen materials, and screen coatings. Today, on April Fool’s Day, 2015, Severtson is making history once again with the announcement of a revolutionary product: a postcard-sized screen that expands to full size as soon as it is thoroughly moistened in water.

“It sounds unbelievable, too good to be true,” said Toby Severtson, CEO of Severtson Corporation. “But this is no joke. We’ve invented cinema screens that increase in size – astronomically expand – when they get wet. With the space-age technology and techniques we use here at Severtson, we can make a screen as small as a postcard which makes shipping a breeze anywhere in the world! All the installers have to do is open the envelope, pour some water on the screen, stand back, and watch the magic happen.”

These “Just Add Water” screens (or JAW screens, for short) are engineered to expand one time, and one time only. They will not contract or expand thereafter, even if exposed to excessive heat, or put in a room with a humidifier. The permanent nature of these JAW screens prevents against possible shrinkage or growth caused by angry movie-goers armed with hair-dryers or water balloons.

Once water is added to the dehydrated screen and the expansion is complete, screens can range in size from small home theater screens to massive sixty-feet-tall and hundred-feet-wide movie screens. Smaller screens will require the addition of less water, while larger screens will require the addition of more water. Roughly, one cup of water is added for every five square feet of final screen size. Again, the initial expansion is final, and therefore crucial. Severtson Corporation is concerned that inexperienced do-it-yourself-ers will attempt to avoid a reputable installer and accidentally apply too much water, resulting in a giant format cinema screen instead of the smaller Mom & Pop sized screen they originally desired.

Perhaps one of the greatest benefits of these new JAW screens is their low cost of shipping. Severtson customers have already seen the savings that have sprung from the ever-popular folded SēVision 3D GX screens that ship in small wooden boxes. Since these JAW screens can fit inside small padded envelopes, shipping costs are reduced to nearly the same cost as a simple letter.

How did the invention of these new screens come about? It all started when Kirk Severtson, CTO and head of research and development, was working on new ways to fit screens into smaller packages. “I was taking a break outside, drinking a cup of water, and thinking. It was a nice morning with a clear blue sky. I gazed down at the water in my cup, and I thought, ‘I love water. Water makes sponges grow. Water makes flowers grow. Why can’t water make movie screens grow?’ And that’s when the idea for the expandable screens came to me.”

From that moment, Kirk pursued the dream of creating JAW screens. But making the dream a reality was another matter entirely. “I knew it was going to be difficult,” said Kirk, “so I consulted a long-time friend of mine who is a lot smarter than me, Dr. April McFoolerson.”

Dr. April McFoolerson is a professor of Hydro-Science and the Physics of Expansion at Foolerton University. When questioned, all April would say is, “Go away! I won’t be revealing my mysterious and multitudinous methods for making movie screens expand with water. My methods are simply too mysterious and multitudinous to be revealed.”

Severtson believes these new JAW screens will be the next big innovation of the cinema screens industry and is ramping up productions to meet their forecasted demand. JAW screens will be available in any of Severtson’s industry respected Stellar White and SēVision GX 3D coatings as well as acoustic transparent options of both standard & micro perforations. Dan Maxwell, COO & VP of the Cinema Screen division at Severtson stated, “Due to our folded screen technology and coating, it has enabled us to create the JAW screen that can be expanded to virtually any size without damaging the screen’s surface or coating. It’s the perfect answer for what was once an impossible scenario for a large format cinematic 2D or 3D screen.”

Paul Whetten, Severtson’s comptroller, is thrilled with the profit potential of the new JAW screens. “The margin on these screens is so unbelievable that I literally don’t believe it. Our liquidity will increase by hundreds of thousands of gallons!” Whetten said thirstily.

Additional specifications of the new JAW Stellar White and SēVision 3D GX Cinema Projection Screens include:

- coated surface that is harder to bruise and scuff

- small micron flake coating produces a sharper image, eliminating graininess in bright scenes

- viewing angles range from 30 to 40 degree half-gain depending on the specific screen gain requested

- water-based coating promotes longevity by maintaining optical properties over time, eliminating flaking and cracking of the screen surface

Utilizing another new technology recently launched by Severtson Screens, very soon dealers will also be able to get immediate cost estimates for the new “Just Add Water” Projection Screen via the new price estimator, which is now live and available for Severtson’s dealer base via its website as well as a mobile app for Apple iOS and Android Smartphones. Once the dealer is registered with an account and granted access at www.severtsonscreens.com/register, the tool provides product and packaging price estimates for Severtson cinema screens as soon as a dealer inputs the necessary required information, such as screen dimensions, coating, material, and desired packaging. The packaging portion of the price estimate is then calculated based on the selected product’s weight and container dimensions, which the tool also provides. For each estimate requested, dealers will receive an automated email and PDF file detailing the screen price and packaging estimate. Prices are only estimates and do not include shipping charges or any other potential international fees.

Severtson Corporation is a member of the Giant Screen Cinema Association and has manufactured cinema screens for theaters in countries all over the world, including the United States, Mexico, Canada, Korea, Japan, Brazil, Indonesia, Singapore, Spain, Germany, France, New Zealand, Australia, Netherlands, Thailand, Scotland, China, Russia, and many more. To meet the challenge of creating extremely large screens, Severtson Corporation designed a robotic spray-arm application system to paint its high-performance optical coating in-house on screens as large as 67.75ft.x 150ft. (20.7m x 45.8m). It is currently the largest in-house cinema screen optical coating system in the world. Severtson Screens certifications and partners include Technicolor, MasterImage, Dolby, Volfoni, LightspeeD & DepthQ, and RealD (www.severtsonscreens.com/literature).

Approaching its 30th anniversary in 2016, Severtson Corporation continues to be a global leader in innovation and quality. The Severtson family’s extensive experience in manufacturing small home theater screens and large cinema screens has given Severtson Corporation the expertise to meet the needs of the professional and consumer AV markets for both indoor applications as well as large outdoor venues. With its three Arizona-based production facilities and its state-of-the-art robotic application system, Severtson has massive production capabilities and an unusually wide array of screens. The screens range in size from massive movie theaters, comfortable home theaters, and everything in between.

Please visit www.severtsonscreens.com, call 480-610-5155, or email sales@severtsonscreens.com.

About Severtson Screens

Mesa, Ariz.-based Severtson Screens, which celebrated its 25th anniversary in 2011, is an award-winning global leader in innovative and quality projection screens in the home theater, pro AV, and cinema markets. Its low rejection rate coupled with the high quality of all its products has made Severtson Corporation the industry standard for quality and customer service worldwide. From its unlikely origins in the family kitchen to today’s three modern production facilities, Severtson Corporation has remained committed to the principles of innovation and uncompromising quality that have made them who they are today.